What are "Nuclear" Procedures?

Commercial nuclear plants have been a big part of the last twenty five years of my life. I’ve spent those years operating, maintaining, evaluating and modifying different size and different design plants with different folks.

But, many things are exactly the same at these plants, paper procedures being one of them. We use procedures for administrative, operating and maintenance, basically whenever we need a step-by-step method to get from point A to point B. There are probably nearly one thousand of them at every station.

While we have a structured system of creating and modifying paper procedures, there are several inefficient and ineffective downsides.

It costs a whole bunch to produce a procedure from scratch, each time. I managed a large engineering group, which included procedure development. It took several people to create and change each one of them and it wasn’t cheap.

Costly Complexity

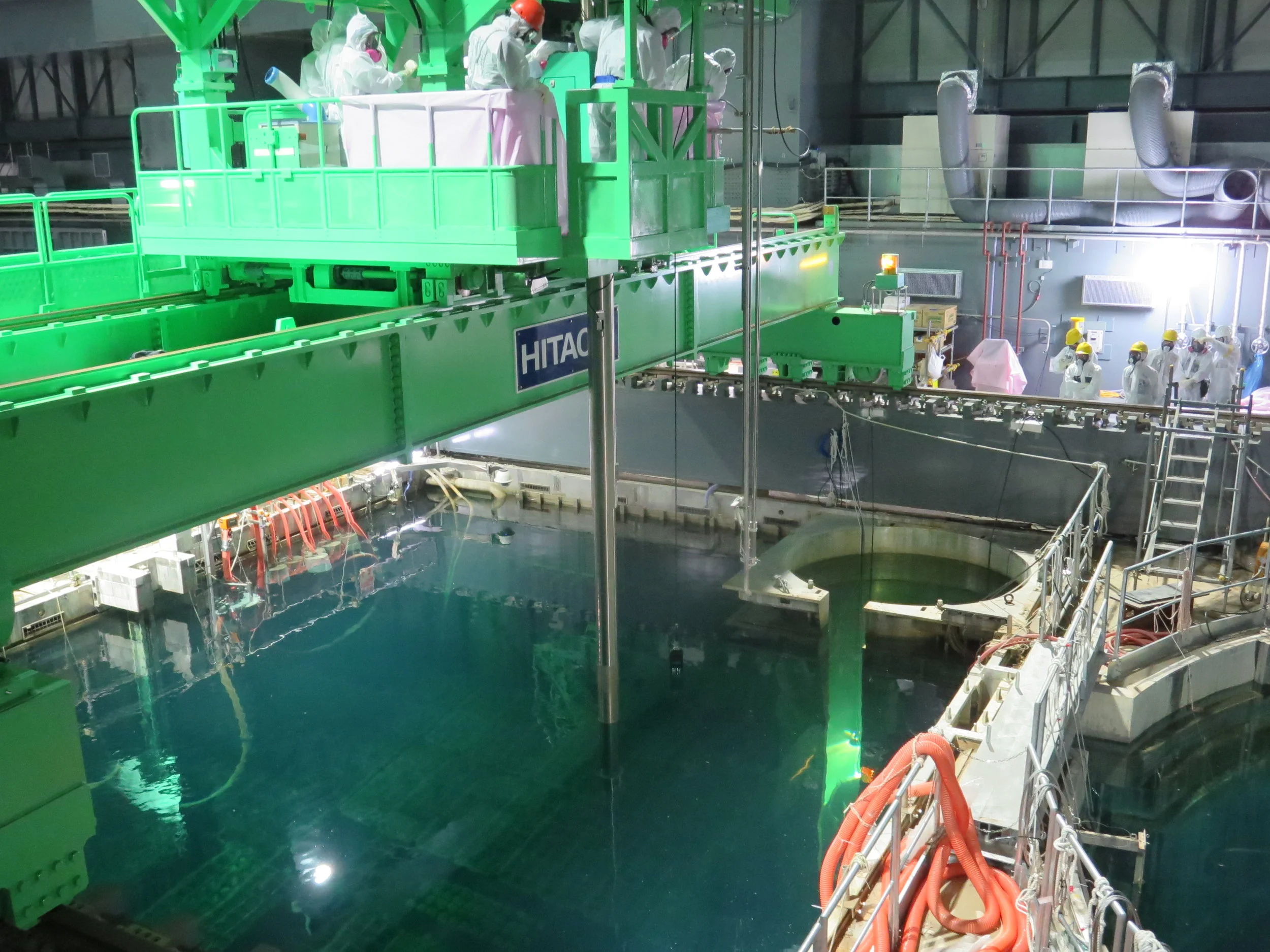

One procedure I remember well, tested a spent fuel transfer crane. Every boundary location had to be tested and it was over 200 pages long and took over two weeks to run. When there was a procedure issue, work stopped, the procedure was marked up and supervision had to sign off.

Yuk.

The worst part was not the effort and money the company spent on those paper procedures, it was the times when the craft missed a step or they recorded an out of specification number or branched to the wrong place.

The consequences were severe.

The person(s) who recorded the wrong value or missed a step were subjected to several interviews, a root cause was written (usually around 75 pages and 60 days to create and approve) and several changes (called improvements) were made to prevent the next poor person from making a similar mistake.

Over time this lead to procedures with many steps that the craft had to migrate through like lawyers.

TurboProcedures?

Why couldn’t our procedures be more like tax preparation software? Automatically branching based on the answer and warnings pop up when something just isn’t right? How about connecting with the existing computer systems to actually tell management where in the procedure the craft was? We had no clue where we were in the procedure execution, we had to call or track down the craft and ask, interrupting their thought process.

I am very optimistic that we are moving toward electronic procedures. People throughout the industry are recognizing the benefits technology can provide to help the craft achieve better results.

I am excited to help the industry I have dedicated my career to transform itself through technology.